Markets

Methanization & Biogas

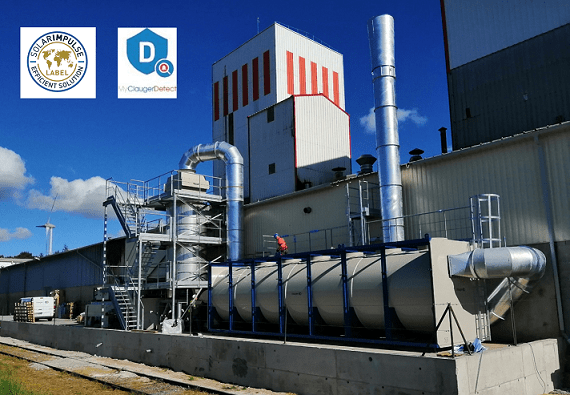

Clauger offers a wide range of “Green Label” solutions, creating added value that can be integrated throughout the methanization process and biogas production.

Clauger combines its expertise in thermal engineering, aeraulics, digital engineering and more to design optimized solutions for odor treatment, decarbonated heating, biogas purification, and CO2 recovery.

These solutions are intended for biogas plant operators, producers and distributors of biogas energy, engineering firms that work in this field, manufacturers of equipment used in biogas production, and partners or process suppliers.

Our Commitments

Commitment to “zero” emissions manufacturing

Optimize energy efficiency, decarbonize your processes

Innovate in biogas purification and enhance the value of activated carbon treatments

Our expertise

Clauger offers solutions that can be integrated at different stages of the biogas production process.

The unique features of Clauger’s solutions include:

- Manufacturing key equipment in Clauger workshops (energy skids, heat pumps (PAC), Biopercolators, Carbon Towers, Scrubbing Towers, Photocatalysis range, and more)

- Using artificial intelligence (AI) and digital tools to control installations and commit to maintaining and optimizing performance over time (Expoll, MyClaugerDetect, etc.)

- Propose an economic model based on CAPEX, OPEX and the return on investment (ROI) of each solution and providing solutions or possible financing solutions, when available.

Odor Treatment: resolving, monitoring and exploiting an odor management strategy

A common constraint encountered during the methanization is the release of odors at the biowaste storage stage, upstream of the fermentation process.

Odor problems can have various impacts:

- disturbing local residents, leading to complaints

- damage the image of your company

Clauger’s odor approach applies 20 years of experience in odor monitoring to propose intelligent industrial deodorization units, thus promoting the cohabitation of people and manufacturing.

We discuss odor management as a holistic strategy that includes four phases: continuous odor measurement and modeling, piloting of the odor risk through Clauger’s products such as Biopercolators and Gas scrubbers, personalized treatment and follow-up on performance indicators.

Related to this topic: Using Odor Treatment Systems for Decarbonization

Decarbonized Heating

As energy costs continue to fluctuate, Clauger uses its expertise in thermal engineering to help you find energy-efficient solutions by recovering waste heat.

The concept consists in capturing available and unexploited sources of heat (waste heat from biogas compression or aqueous discharges), recovering and valorizing them and thus providing “free” heat for new uses (hygienization, heating of digestate in winter, heating of buildings, etc.).

Clauger has the capacity to design, install and maintain heat pump solutions. We offer our own range of heat pumps that can be tailored to suit your specific requirements.

We can also recover heat sources at different temperature levels and store them in a Clauger energy storage battery. The stored heat can then be released at the right temperature level at the right time.

This low-carbon solution reduces the CO2 emitted for heat supply to a methanization installation by 12, improving its overall ISCC score.

Read more about recovering waste heat: Clauger’s Approach to Waste Heat & Energy Efficiency

Biogas Purification

Biogas produced from the methanization process is charged with water and pollutants (H2S, NH3). This requires a dehumidification and purification step.

Clauger offers several solutions:

- a combined solution “Heat exchanger + Chiller ” for the dehumidification of the biogas using the waste heat.

- A range of carbon towers made in Clauger (circular or rectangular) for waste and contaminant treatment.

Our expertise in gas treatment allows us to propose innovative solutions that reduce overall operating costs. Clauger has developed an intelligent EcoTCA that regenerates activated carbon directly on site.

CO2 Recovery

Clauger takes a 360° view of each industrial site and, whenever possible, tries to recover and reuse everything possible from the processes and operations.

Concerning CO2, Clauger offers systems for CO2 recovery and valorization, downstream of the membrane separation.

CO2 recovery allows the transformation of CO2 waste into a product with a market value. Local users such as agricultural and horticultural greenhouses, slaughterhouses, etc. can then be supplied in a shortened production cycle.

Differentiating Products and Services

Our 360 service offer

Related News & Insights

12/07/2023

Clauger and Comtecswiss, two leaders in the industrial sectors, have announced a commercial agreement and strategic partnership for the Biogas and Brewery sectors.

05/05/2023

Clauger offers a different approach to odor treatment: transforming challenges into opportunities, using them as a means to decarbonize industrial sites.

05/05/2023

Aim to achieve a Green Label approach for your industrial site by implementing energy-saving technologies and environmentally friendly practices.