A poorly functioning heat exchanger can affect safety, product quality, and energy costs. In the case of failure, you face costly downtime and potential product loss or contamination. To avoid this, regular and proactive maintenance can preserve performance and help keep operations reliable over time.

Heat exchangers lose performance over time due to fouling caused by routine operations. This fouling, if not resolved, can cause significant performance loss and drive-up energy costs or cause unplanned production stops. To prevent this, it’s recommended to maintain regular cleaning with cleaning-in-place (CIP) systems and also to get heat exchangers repaired and reconditioned regularly.

A well-maintained, clean Plate Heat Exchanger guarantees:

- Safer production: no loss of products – no pollution in the refrigeration circuit

- Maintain optimal energy performance: avoid excessive operating costs linked to fouling or scaling. Preventive maintenance of plate heat exchangers can save you thousands annually

- Compliance with manufacturer recommendations and the CTP regulations for refrigeration systems of July 23, 2020.

The PHE reconditioning service offered by Clauger, or ‘On-site Reconditioning & Cleaning’, significantly increases cleaning efficiency compared to conventional solutions available today by reducing downtime while obtaining the same results as traditional cleaning methods.

Our experienced technicians perform the service on-site to limit production stoppages. They recondition and clean all brands of gasketed plate heat exchangers, using only original parts.

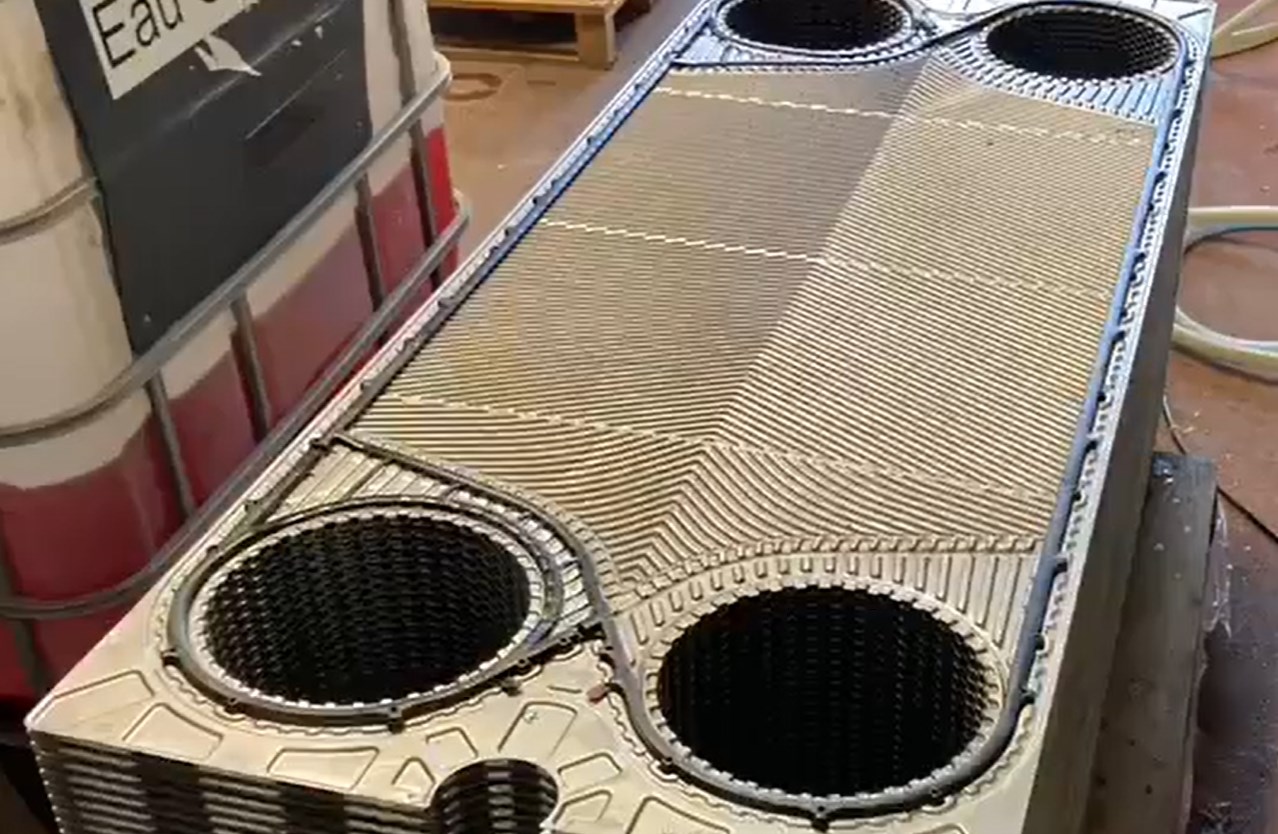

A ‘dirty’ plate before reconditioning Result after ‘On-site Reconditioning & Cleaning’ by Clauger

After the cleaning and inspection stages, the equipment is reassembled. Clauger technicians:

- Validate the heat exchanger performance

- Submit a report with recommendations

- Provide a 24-month warranty on the gaskets.

Our ‘On-site Reconditioning & Cleaning’ service can be included in your regular maintenance contract or as a one-time service. Contact your local Clauger team to set up your on-site reconditioning service today!

Technical Note:

There are two types of plate heat exchangers: plate heat exchangers with clip-type gaskets and plate heat exchangers with glued gaskets.

Our on-site reconditioning and cleaning is unavailable for plate heat exchangers with glued gaskets. This type of equipment requires reconditioning and cleaning at our workshops.

Our specialists then carry out the service in the workshop: arrival inspection, gasket removal, chemical cleaning (liquid nitrogen), post-cleaning inspection, non-destructive testing, new gasket assembly, frame service and reassembly, leakage test, and service reporting.