Cream cheese is made from one or more types of cheese, along with additives such as stabilizers and emulsifiers. These ingredients are mixed, and vacuum cooked, then poured into molds for cooling before packaging. Cooling is a critical step in the production of cream cheese and typically occurs in two phases. Proper cooling ensures a white, smooth, soft texture free from bacteria, lumps, and mold.

The system installed by Clauger reduced the normal two-phase cooling process into a single phase before palletization-after the products are packaged. Our solution dropped the product temperature from 175°F (80°C) to below 104°F (40°C) in 30-60 minutes, depending on the product recipe.

Typically, cream cheese is packaged at 65°C to 70°C and cooled to 40°F. After the first cooling phase, the cheese is then maintained at the target temperature for 15-30 minutes during a ‘slow cooling’ step. The cheese is then stored at a temperature of 40°F until shipping.

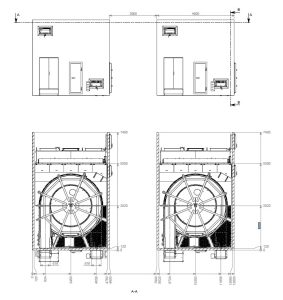

Clauger installed an SMO spiral cooler for this project to streamline and optimize the different cooling phases. The spiral cooler uses direct drive technology to manage the belt system and line stops. This manufacturing site operates year-round, 24 hours a day, 6 days a week, with frequent line interruptions.

Clauger designed this system with free cooling integrated as a function to optimize energy costs. Clauger also installed an ammonia to glycol system (28°F/35°F) using a low-charge Clauger Skid.

Latest articles

This article breaks down IIAR 2-2021 requirements for machine room doors—including hardware, sealing, signage, and access control—and offers practical tips

We’re excited to announce the official launch of Clauger Belgium, our newest subsidiary, operational since February 2025.

Discover Clauger’s marine automation and HVAC retrofit services. Custom PLC panels, global support, and retrofit solutions for marine HVAC &

- #Alternative proteins

- –

- #bakery

- –

- #canada

- –

- #cheese

- –

- #chemistry

- –

- #chile

- –

- #china

- –

- #colombia

- –

- #dairy

- –

- #e-streaming

- –

- #Eficiencia Energetica

- –

- #france

- –

- #fruit-vegetables

- –

- #italy

- –

- #jobs

- –

- #logistics

- –

- #Marine

- –

- #meat-poultry

- –

- #methanization

- –

- #Methanization-Biogas

- –

- #mexico

- –

- #Mexico-EN

- –

- #Midlle-East

- –

- #myclaugerdetect

- –

- #pharmaceutical

- –

- #Prepared foods

- –

- #process-gas-energy

- –

- #PSM

- –

- #References

- –

- #Refrigerantes naturales

- –

- #RSE

- –

- #russia

- –

- #service

- –

- #Service

- –

- #Skid

- –

- #smo

- –

- #spain

- –

- #swiss

- –

- #United States

- –

- #united-states

- –

- #values